Plasma Enhanced Chemical Vapor Deposition (PECVD)

Brand: MVS Systems Inc.

Model: N/A

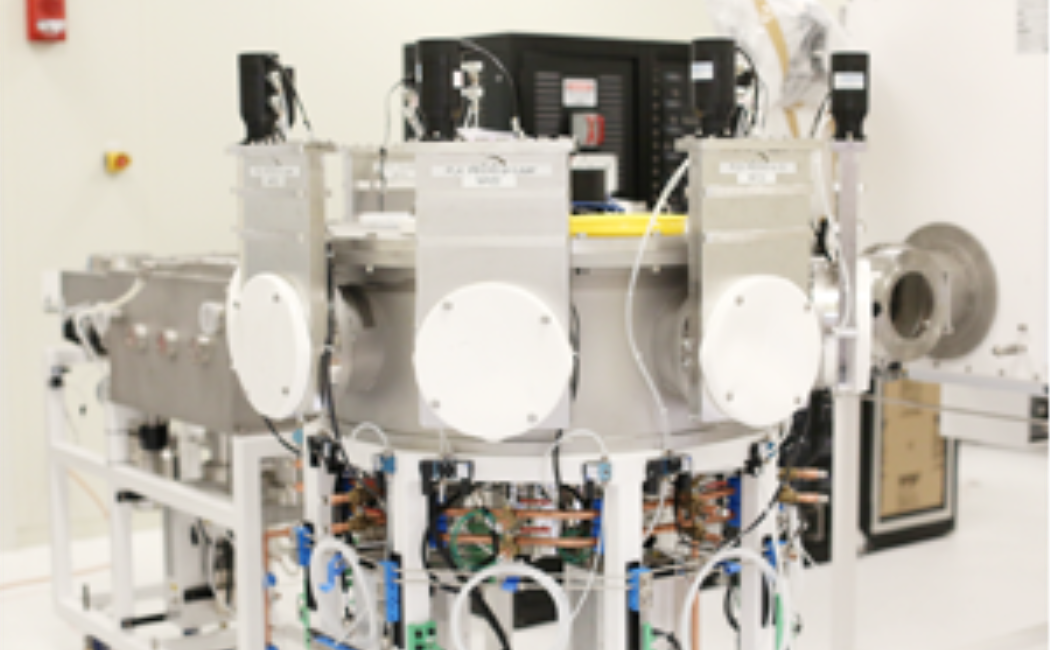

This multi-chamber Deposition System (Cluster Tool) is designed to deposit thin-film semiconductors (e.g., a-Si, nc-Si, p+Si, n+Si) and dielectrics (e.g., SiNx, SiOx) by PECVD, transparent conducting oxides (ITO, AZO), and metals (Al) by sputtering. The system was built as a research and development tool for the coating of rigid 15.6 cm X 15.6 cm (or smaller) substrates, which are placed in a stainless steel carrier.

The computer-controlled multi-chamber PECVD/Sputtering system accommodates six modular process zones (MPZs), one load lock (LL), and one park station around a central isolation and transfer zone (ITZ). The load lock is connected to a glove box. The system consists of five PECVD chambers and one sputter chamber. See Figure below for the layout and brief description of the system. Deposition occurs upwards in all chambers, which minimizes the occurrence of pinholes in the films.

Pumping of chambers is accomplished by turbo pumps backed by RV pumps. The PECVD chamber at PL3 is pumped using a roots pump during processing. Throttle valves are mounted between chambers and turbo or roots pumps for pressure control during processing.