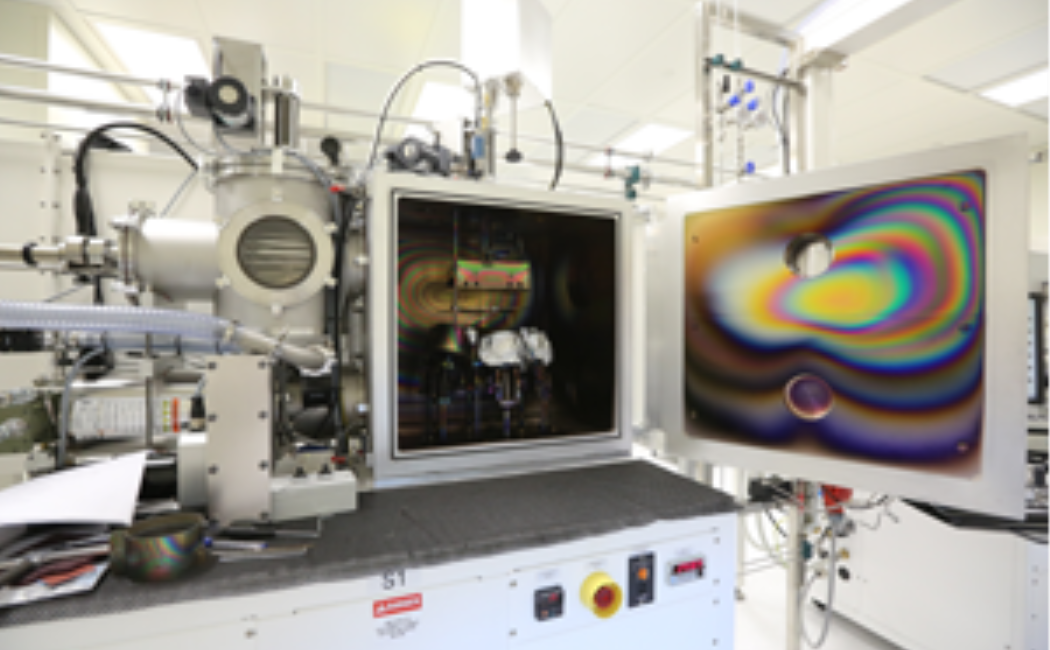

Angstrom Engineering Amod Sputter Deposition

Brand: Angstrom Engineering

Model: Amod Sputter Deposition

How does sputtering work? Sputtering is a physical vapor deposition (PVD) coating technology. By creating a strong magnetic or electrical field during the sputtering process, high-energy ions and electrons, generated in a plasma of an inert gas, are confined to a designated area close to the source target. This causes a cascade of collision events on the target material, which is then ejected onto the substrate with a high deposition rate. Magnetron sputtering helps reducing film damage since the magnetic field prevents electrons from bombarding the substrate. Importantly, this deposition technology allows to deposit films of materials that are usually difficult to evaporate such as certain metal oxides.

Our system is configured to support two types of sputter deposition: RF sputtering, DC sputtering. Each of these deposition methods uses a process sputter gas, which is usually an inert gas like argon with reactive gases added for certain processes.

We are using our sputtering systems to deposit many metal oxides, which can be used, for instance, as transparent conductive layers in solar cell applications.